Shin Nakajima: Should the motor core be made of amorphous alloy or electrical steel? My choice basis and magnetic circuit theory have this thinking

May 05, 2024Motor energy saving and core material development

Today, it can be said that more than half of the total global electricity consumption comes from motors. High-efficiency motors are urgently needed to control carbon dioxide emissions and thereby curb global climate warming.

The key to achieving this high-efficiency motor is the core material. The core material of the motor, as the name implies, is made of iron-containing materials. The core material is made of magnets and plays an important role in controlling the magnetic flux of the motor (forming a magnetic field), but it also becomes a source of heat due to iron losses (hysteresis loss and eddy current loss).

So, will it be possible to achieve high efficiency of the motor by choosing a core material with small iron loss? Not so.

Core materials have many properties. Moreover, even the same core material has different required properties when used in motors and when used in transformers. In recently developed high-efficiency motors, amorphous alloys are used instead of non-oriented electromagnetic steel sheets as core materials, and combined with ferrite magnets, ultra-high efficiencies previously thought to be impossible have been achieved. This article will explain the selection and use of motor core materials based on this case.

Core materials can be divided into two categories

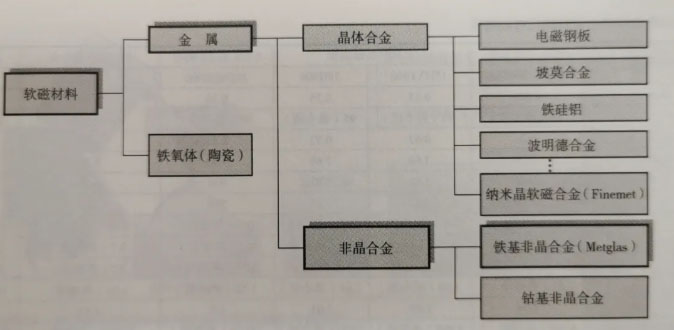

Core materials are also called soft magnetic materials. Figure 1 shows the main soft magnetic materials.

What kind of motor core material is better?

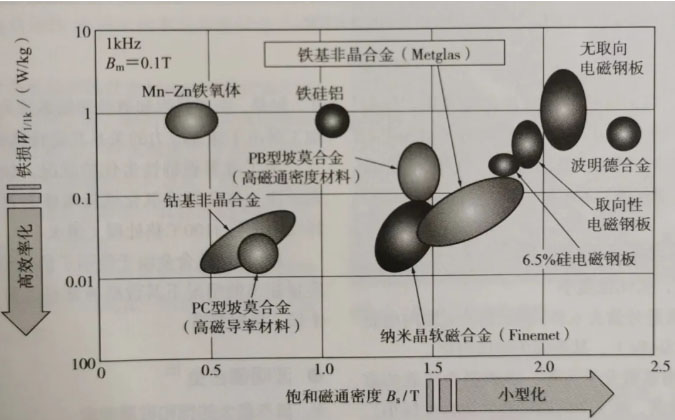

If there is no heating effect of iron loss, using soft magnetic materials with large Bs in the core can obtain the maximum magnetic flux density Bm of the core. In addition, the volume of the core is inversely proportional to the square of Bm. From the perspective of miniaturization, materials with large Bs also have advantages.

On the other hand, from the perspective of improving efficiency, soft magnetic material cores with small iron losses are preferred. Therefore, high-quality soft magnetic materials with high Bs and low iron loss located in the lower right area of Figure 2 are needed. However, as shown in Figure 2, there is a compromise between high Bs and low iron loss, and the ideal soft magnetic material that can satisfy both does not exist.

It can also be seen from Figure 2 that when the frequency is 1kHz, in terms of high Bs, Perminde alloy has advantages; in terms of low iron loss, nanocrystalline soft magnetic alloy and PC-type permalloy (high magnetic permeability material) are more advantageous. Advantage.

Comparing iron-based amorphous materials and non-oriented electrical steel sheets

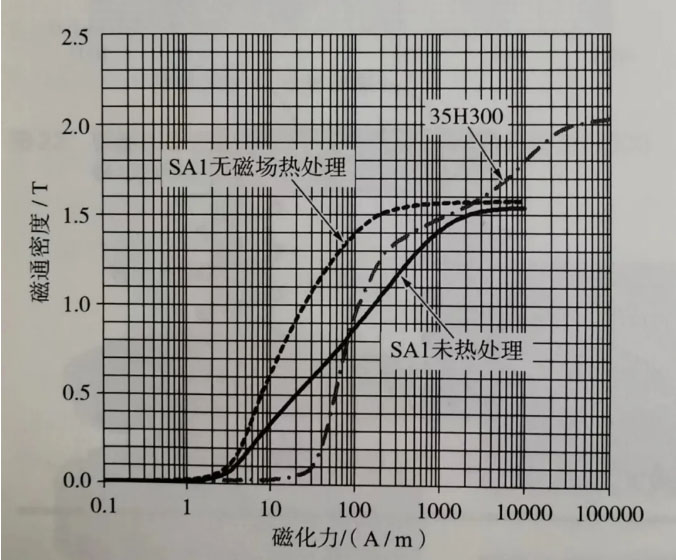

Comparison of the initial magnetization curves of iron-based amorphous alloy SA1 and non-oriented electromagnetic steel plate 35H300 is shown in Figure 3.

For SA1, in order to relax the stress exerted on the alloy during casting, the magnetic properties can be improved through magnetic field-free heat treatment in a nitrogen atmosphere. However, since SA1 will become embrittled under heat treatment, heat treatment is mostly not performed when used in motors. When it exceeds B-0.8T, the magnetizing field strength of SA1 becomes greater than that of 35H300 (the magnetic permeability becomes smaller).

Evaluate core processing

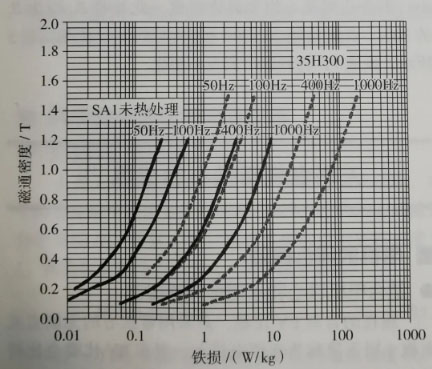

Figure 4 shows the iron loss comparison between SA1 and 35H300 slotted and cut cores without heat treatment. In the case of 400Hz and B.=1.0T, the iron loss of the SA1 core is 2Wkg and the iron loss of the 35H300 core is 20Wkg. The former is 1/10 of the latter. Based on this, it is extremely effective in improving the efficiency of motors, such as in battery-driven motors, and has the effect of extending battery life.

In addition, the higher the driving frequency, the greater the iron loss difference between the two. This situation also applies to high-speed motors.

Figure 5 shows the structure of an 11kW double-rotor axial gap motor, which uses an SA1 stator core and a ferrite sintered magnet rotor. The stator core is a simple structure in which amorphous alloy SA1 is cut into long strips, laminated, and fixed with resin. It is a slit-cut core.

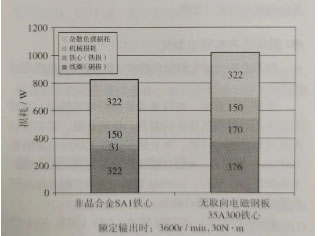

The stator core is made of non-oriented electromagnetic steel plates of the same shape, which are cut into long strips and then laminated and fixed with resin to obtain another motor. The loss comparison between it and the motor shown in Figure 5 is shown in Figure 6. Compared with the 35H300 stator core, the SA1 stator core can reduce the iron loss by 1/5. In addition, by reducing the excitation current, the copper loss can be reduced by about 15%, reaching an efficiency of 93.2% in line with the IE4 standard.

Furthermore, on the basis of this motor, the characteristics of amorphous alloy are fully utilized, which is smaller than the traditional three-phase induction motor. A high-efficiency motor that meets the IE5 standard is being developed.

Read more: https://www.hemeielectricpower.com/